Things OS

Things OS is a cloud-based operating system designed to power digital twins (Things Twins) and AI applications on industrial machines in a secure environment.

Things Twin

This high-performance data-based digital twin of your machines gives you unrivaled analysis, process insights, and automatic condition monitoring.

Plug and produce

Our enterprise solution can be combined with powerful hardware, connects via LTE, and is ready in a few clicks - no network expansion or security upgrades needed.

High-performance

Digital Twin

Things Twin

optimizes operations

Extraordinary analytics

The Things Twin automatically performs industry- and machine-specific analyses of process data. It provides your production management with the results as a decision-making aid.

If desired, the Things Twin can also directly intervene in the process.

Parameterize processes better

The insights enable you to intervene in the production process more quickly and accurately.

The Things Twin allows you to:

Reduce machine downtime

Minimize energy and material waste

Deploy personnel more effectively

Be less dependent on specialists

Across all machine types & brands

One of the biggest advantages of Things OS is that it can be used independently of machine manufacturers. Use the insights, for example, for Trumpf and Eurolaser cutting systems at the same time.

Tomorrow Things specialties:

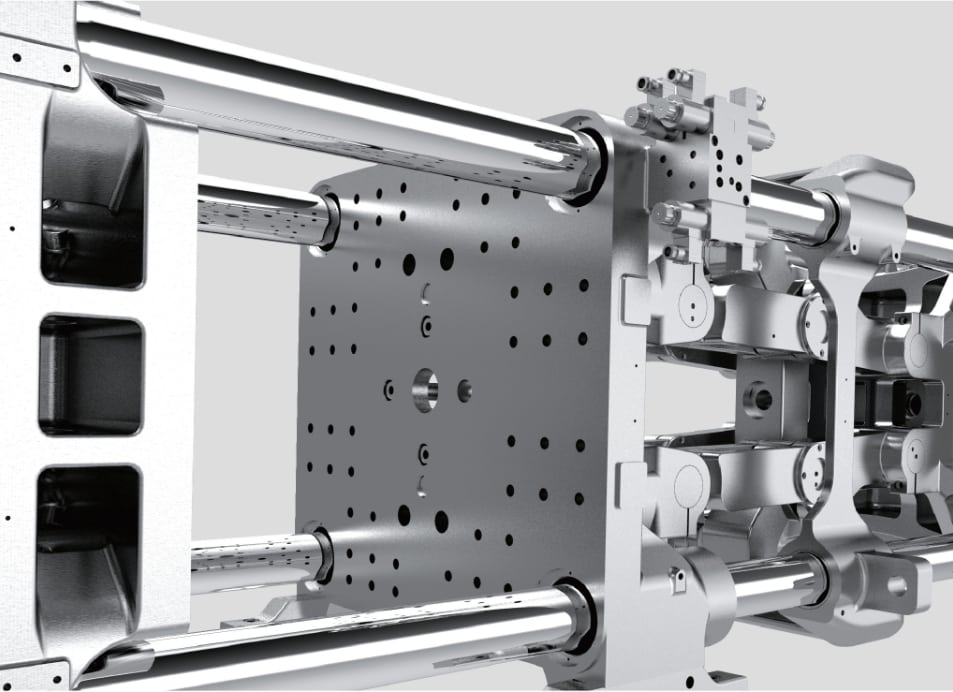

Plastics processing

Packaging machines

CNC machining systems

Examples of groundbreaking insights in the field of plastics processing

Monitor

critical process parameters and Setpoints

Threshold values

With our machine blueprints, threshold values for process parameters and setpoints are set automatically - no self-service required.

You can fine-tune these ranges yourself or have them adjusted by dynamic micro-models.

Adjustments for product and tool changes are also possible.

Automatic alarms

If critical process parameters are exceeded or fall below the set thresholds, the right contact person in your company will receive a notification.

Likewise, micro or AI models can trigger alerts to inform you at the earliest possible stage.

This enables you to react quickly and take action, reducing scrap and downtime.

Data history

Additionally, you can display the history of all data points and setpoints as a chart.

This helps you identify outliers and set the right threshold values.

The condition monitoring of Things OS enables efficient and fast usage.

Visualization

on point

Things Twin results

The machine dashboard is your interface to the Things Twin of your machines. It provides a clear overview of all live process data, analysis results, and micro-model insights at a glance.

Powered by Blueprints

The dashboards are automatically provisioned and tailored to each machine type using our blueprint technology - eliminating any administrative effort.

Key insights and KPIs

All key KPIs for your machine are automatically summarized, and the insights are visualized in an intuitive way.

Improve auditability

The Things Twin makes the complete data history of all process data available. Simply jump back in time as required.

Manufacturer-independent

A major advantage is the ability to monitor all machines of the same type (e.g., laser cutting systems) consistently. Regardless of the brand and manufacturer, you only need one software solution: Things OS.

Location independent

With Things OS, you can access and monitor your machine dashboards from any location.

Digitalization

with one click

Extremely fast

Things OS is ready in a few clicks - no IT knowledge needed. With a secure LTE connection, no network expansion or security upgrades are required. You can get started with the digitalization of your machines straight away.

Cost-saving

No system integrator is needed to connect your machines to the cloud, saving coordination and integration costs. Plus, the Things Twin is automatically available at a fraction of the usual digital twin cost.

Heterogeneous machine parks

Many of our customers have diverse machine parks, all natively connectable to Things OS. Plus, machine-to-machine and enterprise software interfaces can be enabled with just one click (see Things Apps).

Step 01: Hilscher Compact Edge Gateway

Your retrofit solution:

We collaborate with the leading manufacturer of industrial communication — Hilscher Gesellschaft für Systemautomation mbH.

Hilscher and Things OS form the perfect combination, offering highly secure edge connectivity with robust hardware, paired with the automated creation of Things Twins for your machines and systems.

You receive the powerful Hilscher Compact Edge Gateway, which you simply connect to your machines via plug and play.

Step 02: Auto-provisioned Things Twin

As soon as the gateway is installed, the Things Twin is created with just a few clicks.

Why is this process so simple and cost-effective?

Because we rely heavily on standardization and auto-provisioning. Things Twins are unique in the industrial landscape and exceptionally powerful.

Blueprints – the technology behind it:

With Blueprints, we can fully automate the extraction of relevant data points for each machine type, create dashboards, activate powerful micro-models, and provide you with valuable insights.

Step 03: Ensuring highest data quality

From now on, all relevant operational data, events, error codes, etc., will be continuously collected. You will benefit from the highest level of:

Data quality

Data sovereignty

Data security (find out more here)

future-proof

And AI ready

Things Apps

Enhance Things OS with powerful Things Apps. Leverage full AI power or use Things Control for remote machine operation, among other capabilities.

Things SDK

Optionally set up and run dedicated calculations and AI models for your systems using our Things SDK.

Things API

The Things API enables you to maximize integration and make profitable use of your machines' process data.

If you are purchasing new machines, we recommend including Things OS in your specifications. This incentivizes machine builders to offer you value-added, cost-effective packages. For example, you can then take advantage of Tomorrow Things’ cost-saving remote maintenance (Things App: Things Support).

Feel free to contact us if you have any questions!